Shingle Sealants Bond Your Roof Together

With ever increasing performance expectations for asphalt shingles designed to withstand high winds and heavy rains, manufacturers have responded by producing increasingly higher-performing shingles. When properly installed, asphalt shingles are manufactured to bond securely to each other, forming an integrated roof-covering system designed to protect your home from the elements.

What is the secret ingredient? Asphalt-based bonding sealants create the tie that binds!

How Are Shingles Attached to the Roof Deck?

Asphalt shingles are manufactured as individual units and are installed in courses along the roof. When properly installed, the shingles adhere to each other to form a cohesive roof-covering. Initially, make sure that the wood deck is in good condition, then, assure that the right underlayment material is properly attached to the roof deck. The underlayment provides extra protection for roof decking materials, and keeps the shingle materials from adhering directly to the deck over time.

Nails and the Roof Deck

The best way to ensure that asphalt shingles are properly attached is to follow the manufacturer’s installation instructions. As each asphalt shingle course is laid out, roofing nails secure the shingles to the roof deck. Here are a few nailing practices recommended by many shingle manufacturers.

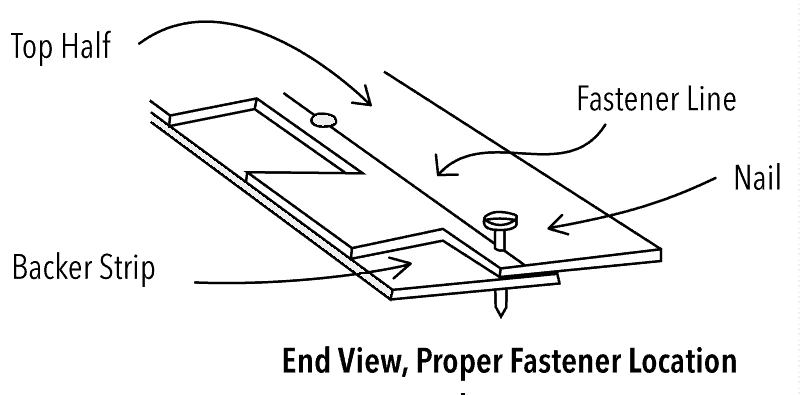

It is important to make sure shingles are attached to the deck by using the proper type, size and quantity of nails. Make sure the nails are in the right place by driving them in the indicated “nailing zone.” Always ensure that nails in laminated shingles are driven through the double thickness overlap area as indicated in this diagram.

How Does the Sealant Work?

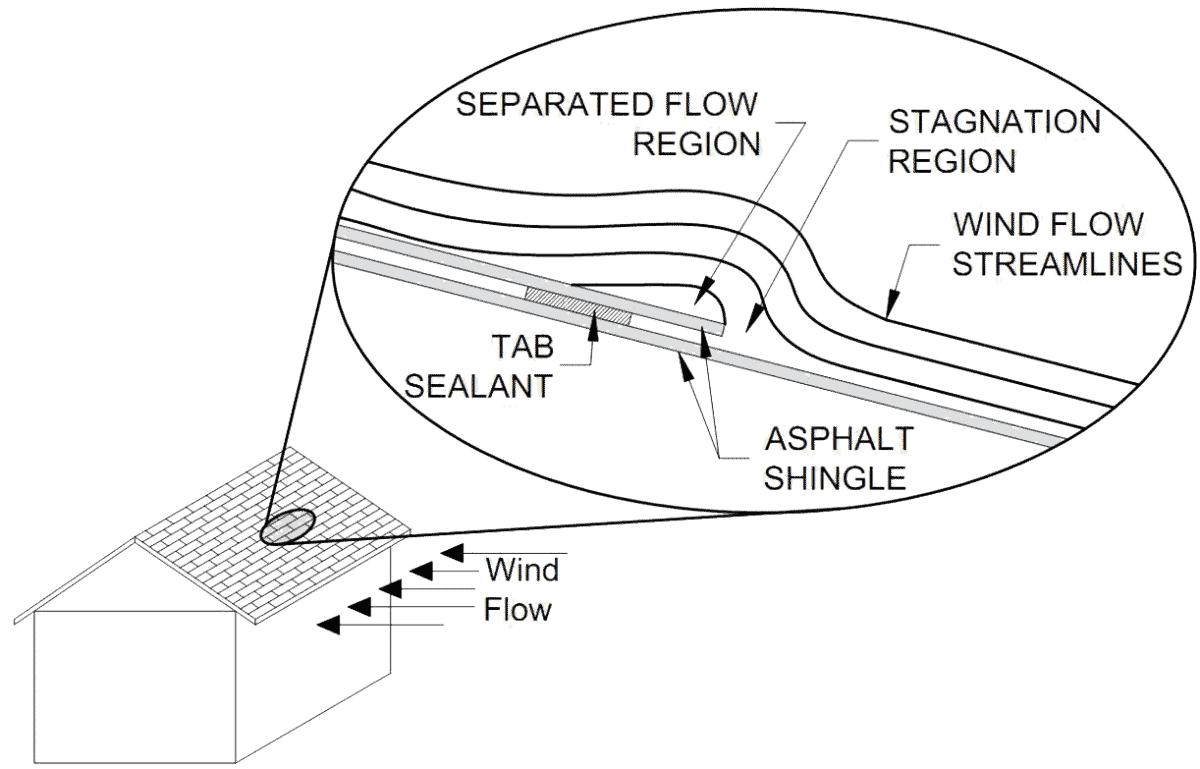

Once each course of asphalt shingles is attached to the roof deck, every subsequent shingle course will bond with the previously installed course, with the asphalt-based sealant fusing the shingles together. The bonding sealant is factory-applied on the shingle (front or backside), so following the manufacturer’s instructions regarding spacing and alignment are critical for a proper sealant bond. Heat and UV rays from the sun activates and softens the sealant to create the necessary bond needed to provide good wind resistance for the finished asphalt roof covering system. Once sealed, the bond is designed to hold the asphalt shingles together as a complete system.

What Are Sealants? An asphalt based, heat activated, viscous bonding material formulated to retain bonding strength in all weather conditions, once initial bonding has occurred. Sealants are used on asphalt shingles to bond the individual unit shingles together.

The Importance of Proper Installation

Recent research conducted by the University of Florida’s College of Engineering1 has concluded that proper installation is an important and very critical factor to ensure that the shingle sealant bonds the shingles together as designed.

Industry performance standards for asphalt shingles include testing of the sealant bond under laboratory conditions. These tests are intended to simulate the resistance of the shingle to uplift forces created during wind events. Selecting a shingle that meets or exceeds local wind-speed requirements in the building code will help your roof covering withstand windstorms and protect your home. Asphalt shingle design has to ensure compliance to ever-changing building code requirements. Shingles have always worked as an effective wind-resistant roof covering, and now, thanks to the use of bonding sealants, they work even better to keep out the elements.

1Masters, Forrest J. Ph.D., P.E. (FL) (2013). Phase II Report: Investigation of the Wind Resistance of Asphalt Shingle Roof Coverings (SERRI Report 90100- 02). Florida: University of Florida.

How Can I Make Sure the Sealant Does its Job?

Be aware of these key elements…

• Local code requirements matter. Manufacturers test asphalt shingles to the requirements of local building codes. Check with the manufacturer to verify the shingle you select is appropriate for use in your area.

• Schedule your roofing project to consider weather conditions. Asphalt shingles can be vulnerable to wind forces until the sealant bonds, so it may be best to install your roof when the temperatures are well above freezing. Heat and UV rays from the sun activate the sealant to bond the shingles together. Check to make sure that severe weather, including heavy rain, dust storms, snow and high winds, are not in the forecast.

• The manufacturer’s installation instructions are your guide to a properly-attached asphalt shingle roofing system.

• Proper sealing starts with proper nailing. Always follow the manufacturer’s instructions and use the right fasteners for the job, and make sure the shingles are properly placed. Be sure that the nails are placed within the prescribed nailing zone and are driven flush with the top surface of the shingles as required by the manufacturer.

• For more information about Florida Building Code Requirements for asphalt shingles, click here to read the ARMA Technical Bulletin.

What about that mysterious little cellophane strip?

Asphalt shingles are packaged for shipping in bundles, so most manufacturers apply a strip of material between the shingles to keep them from adhering into one big shingle brick! Once the shingles are separated, the strip is in an area that will have no effect on the performance of the shingle.

It is not necessary or desirable to peel off those strips.