Revised September 2022

BY PAUL SCELSI

*This article was originally published by Roofing Magazine

Good news, roofing contractors: You do not have to be good with numbers nor do you have to enjoy math to be able to quickly—and accurately—calculate the amount of attic ventilation needed for residential attics. Here it is, a handy shortcut for quick calculations:

Attic floor square footage ÷ 2 = square inches of EXHAUST and square inches of INTAKE Net Free Area (NFA) needed. (NFA is the unobstructed area through which air can pass through a vent, usually measured in square inches. Ventilation manufacturers assign an NFA value to the non-motorized vents they make.)

This shortcut conveniently calculates the 2021 International Residential Building Code MINIMUM (IRC Section R806 – Roof Ventilation 1) which states, in part, 1 square foot of Net Free Area for every 150 square feet of vented space (attic floor area) with the attic defined as length x width floor of the attic). The shortcut actually overestimates a bit but that’s OK. It puts the roofing contractor in the ballpark which is useful when estimating.

To calculate the allowable IRC EXCEPTION to the MINIMUM (that is, 1/300 ratio) here’s the shortcut:

Attic floor square footage ÷ 4 = square inches of EXHAUST and square inches of INTAKE Net Free Area needed.

Here’s an example using the shortcut for the 1/150 Code Minimum.

Say the contractor is standing in front of a house that has an attic with 2,200 square feet.

2,200 ÷ 2 =

- 1,100 square inches of EXHAUST net free area needed

- 1,100 square inches of INTAKE net free area needed

The next step is to select a suitable exhaust vent and intake vent that fits the roof design for best performance and best aesthetics. After that, find out the vent’s NFA as rated by the manufacturer. Divide the vent’s NFA into 1,100 to yield the number of vents needed (either in linear feet or units/pieces). That’s it. It’s time to install.

There is a longer “official” formula based on building code you can reference or point your clients to for reassurance that you know what you’re talking about. Most attic ventilation manufacturers list the longer formula on their websites and inside key product brochures. But the shortcut is just as good and faster!

Calculation Q & A

Here are the answers to the five most frequent questions pertaining to calculating attic ventilation.

1. “Why is it important that the amount of intake ventilation matches the amount of exhaust?”

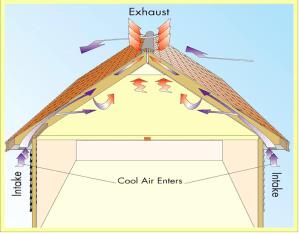

The goal of an effective attic ventilation system is to help fight heat buildup inside the attic during the warmer months and moisture buildup in the colder months. Additionally, in climates where snow and ice are common, attic ventilation can help fight the formation of ice dams. To achieve these goals the attic needs cooler, dryer air entering low (near the eave or the roof’s lowest edge) so it can flush out any warm, moist air that may have built up inside, pushing it out through the roof’s exhaust vents positioned as close to the peak as possible. This balanced-airflow approach allows the air to “wash” the entire underside of the roof deck from low to high.

2. “What if it’s not possible to balance the attic ventilation system 50 percent intake/50 percent exhaust?”

If it cannot be balanced it’s better to have more intake than exhaust because it has been industry experience most attics lack proper intake ventilation, which is the leading cause of venting callbacks. Additionally, any excess intake will become exhausted on the leeward side of the house because the intake vents on the windward side of the house will have “pressurized” the attic. As a result, the intake vents on the leeward side of the house will work “with” the exhaust vents to release air.

However, if the attic has more exhaust than intake it potentially can cause the extra exhaust to pull its missing intake from itself (if it’s a ridge vent) or from another nearby exhaust vent (from one wind turbine to another or one roof louver to another), which means possible weather ingestion.

3. “What if the roof has 40 feet of available ridge length but the math calls for only 30 feet of ridge vent needed?”

It is OK to install all 40 feet of ridge vent as long as it can be balanced with intake ventilation. If the amount of intake ventilation cannot match the entire 40 feet of ridge vent, consider reducing the width of the ridge vent slot (thereby reducing the vent’s NFA per linear foot) to accommodate the amount of intake NFA available. Doing this keeps the airflow continuous along the entire horizontal ridge and balanced high and low. As always, be sure the overall amount of ventilation meets code requirements.

4. “If attic access is not practical is there another way to measure the attic floor square footage?”

Ideally, the attic floor square footage would be measured at the attic floor length x width (regardless of roof pitch, by the way). If this is not possible, and the homeowner does not have any documentation on file listing attic floor square footage, you could use the footprint of the house (aerial view of the house) or the number of shingle squares (one shingle square equals 100 square feet) to estimate the attic floor square footage. Neither of the alternate measuring tactics, however, is as accurate as an attic floor measurement.

5. “How does roof pitch come into play when calculating attic ventilation?”

Current IRC requirements do not factor the role a roof’s pitch plays in the amount of attic ventilation needed, but ventilation manufacturers do. Generally, as the roof pitch increases the volume inside the attic also increases along with the amount of needed attic ventilation. Here’s a rule of thumb to follow:

- Up to 6:12 roof pitches use the standard formula as explained in this article.

- 7:12 to 10:12 roof pitches increase the amount of ventilation by 20 percent.

- 11:12 roof pitch and higher increase the amount of ventilation by 30 percent.

For projects involving vents with motors, the calculation formula is different. Refer to the vent manufacturer for more information.